Aluminum extrusions are foundational to contemporary manufacturing and construction, presenting a harmonious blend of flexibility, resilience, and eco-friendliness. As we explore the realm of aluminum extrusions, we’ll uncover the artistry involved, their myriad benefits, wide-ranging applications, and more.

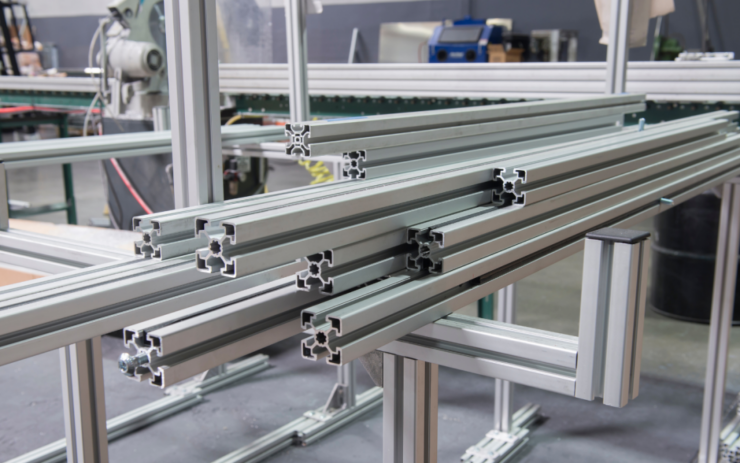

Aluminum Extrusions

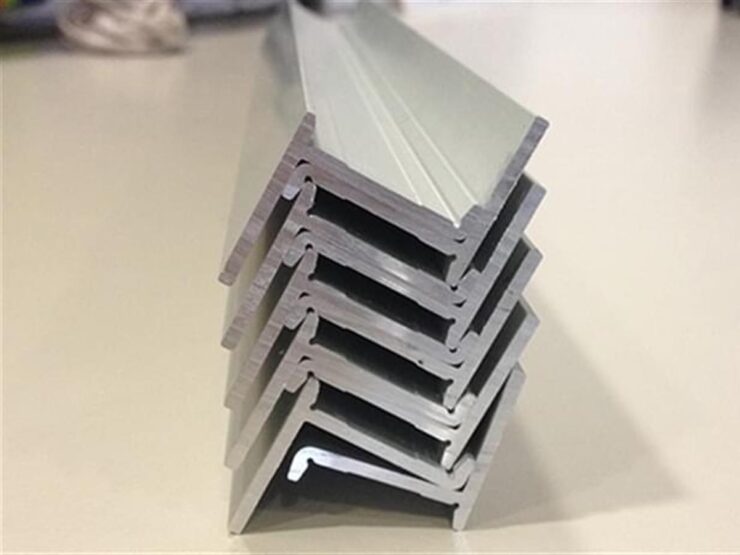

A technique where aluminum alloy, including the high-strength 7075 aluminum extrusions, is transformed into objects with specific cross-sectional profiles. This transformation occurs when the aluminum is forced through a shaped opening in a die, resulting in it adopting the shape of the die as it emerges on the other side.

The inclusion of 7075 aluminum extrusions in this process speaks to the versatility and adaptability of the method, catering to various strength and application requirements.

Pro Tip: The extrusion process can be likened to squeezing toothpaste out of a tube. The toothpaste takes the shape of the nozzle, just as the aluminum takes the shape of the die.

The Craftsmanship

Crafting quality aluminum extrusions requires a deep understanding of the material and the extrusion process. Skilled craftsmen ensure that the metal is heated to the right temperature, the die is meticulously designed, and the extrusion speed is maintained to produce consistent and high-quality profiles.

Advantages

- Versatility: Aluminum can be extruded into a vast array of shapes and sizes.

- Strength: Despite being lightweight, extruded aluminum profiles can be incredibly strong.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, making it resistant to corrosion.

- Thermal Conductivity: Aluminum extrusions are excellent conductors of heat, making them ideal for heat sinks and radiators.

Diverse Applications

From towering skyscrapers to the smartphone in your pocket, aluminum extrusions play a pivotal role in various industries:

- Architecture and Construction: Used in window frames, curtain walls, and structural components.

- Automotive Industry: Essential for lightweight vehicle frames and components.

- Aerospace and Aviation: Key for aircraft structures due to its strength-to-weight ratio.

- Electronics and Electrical Industry: Found in heat sinks, casings, and other components.

- Consumer Goods: Used in appliances, furniture, and even sports equipment.

- Renewable Energy Sector: Crucial for solar panel frames and wind turbine structures.

Fun Fact: The Eiffel Tower, one of the world’s most iconic landmarks, was painted with 60 tons of paint to protect it from rust. If it were made today using aluminum extrusions, it would not only be lighter but also wouldn’t need such protective measures!

Innovations

Innovations, such as the use of advanced alloys and precision dies, have allowed for even more intricate and durable profiles. Additionally, computer-aided design (CAD) has revolutionized the way dies are crafted, ensuring precision and consistency.

Sustainability and Environmental Considerations

100% recyclable, and its recycling process requires just 5% of the energy used to produce the original metal. This makes aluminum extrusions a favorite for industries aiming for sustainability.

Challenges and Limitations

While aluminum extrusions offer numerous benefits, they aren’t without challenges. Factors like alloy selection, die design, and cooling rates can impact the final product’s quality. Moreover, there’s a learning curve involved in mastering the extrusion process.

Conclusion

Aluminum extrusions have undeniably shaped the trajectory of multiple industries, offering a blend of versatility, strength, and sustainability. As technology advances, we can only anticipate even greater innovations and applications for this remarkable process.