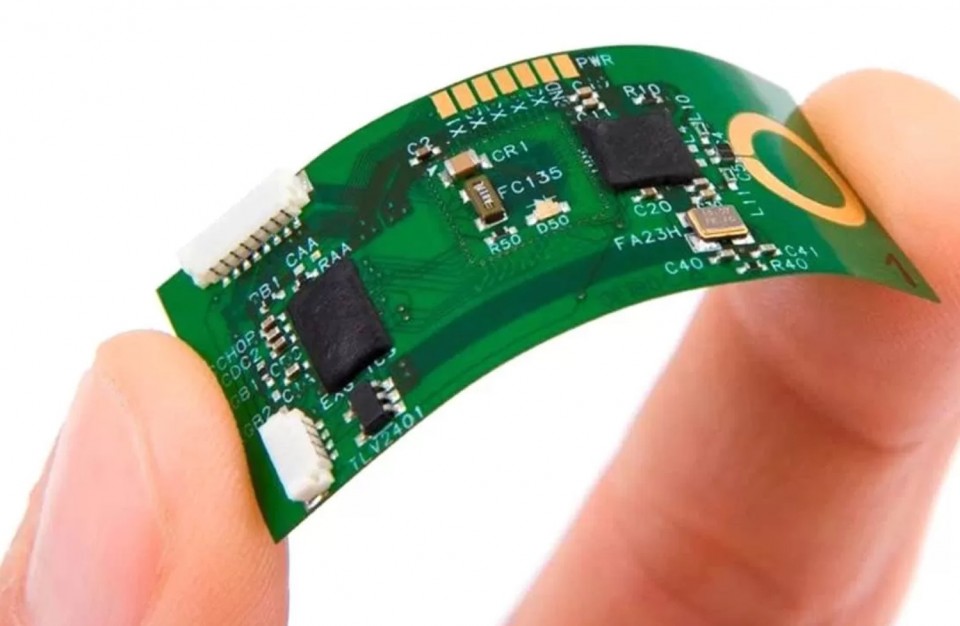

Printed circuit boards are one of the most important parts of every electronic device. They are used in pretty much every industry, and they use conductive tracks to support and connect the electronic components. The traditional PCBs are rigid, and this has led to different issues in many industries. The flexible printed circuit boards are said to have revolutionized electronic interconnection techniques and in this article, we are going to talk about some of the pros and the cons that come with using elastic boards. Continue reading to learn why many manufacturers are choosing to produce only the flexible models, and why some experts suggest that they will never replace the traditional, rigid units.

1. Better quality

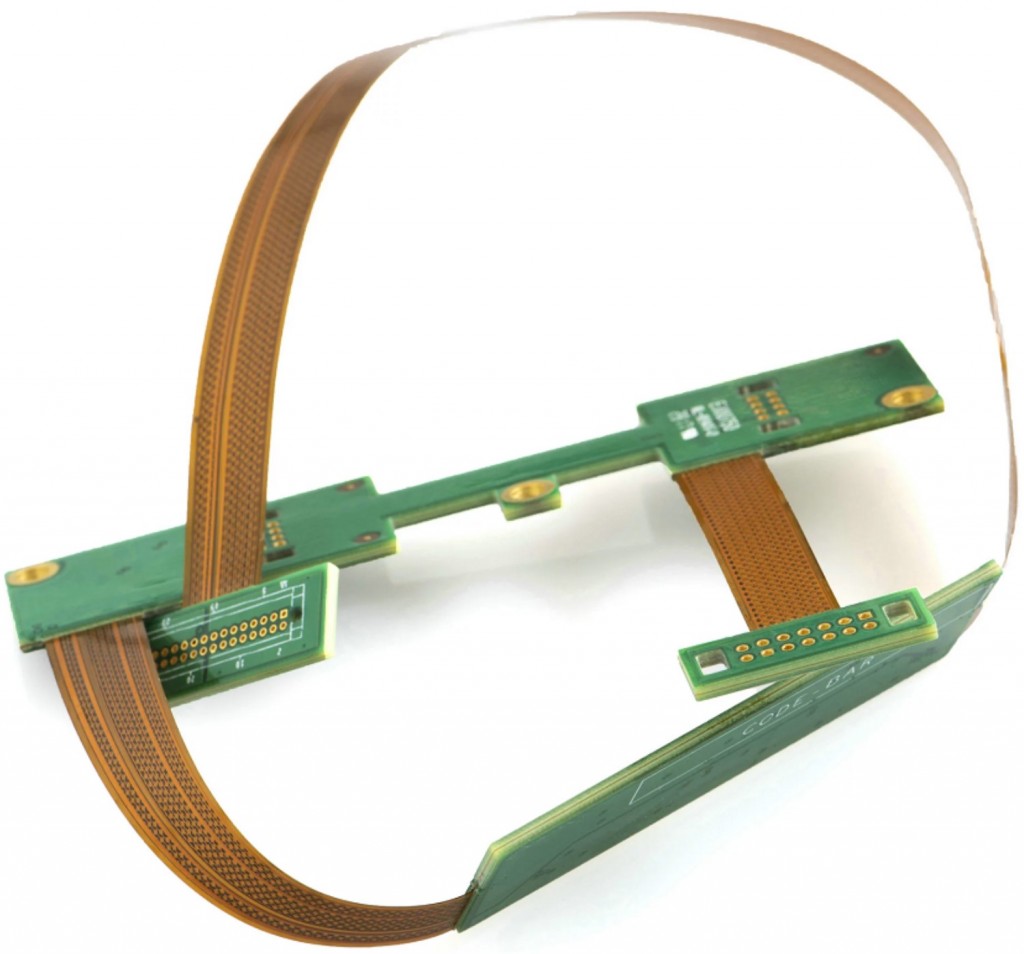

The first advantage of the FPCBs we are going to talk about is the improved overall quality of the unit. When these items are manufactured, the flexible units are much more simple to create than the rigid ones. In addition to this, these parts are easier to install and connect to the devices. You won’t have to be as precise, and you won’t have to spend a lot of time figuring out the board, what you need to connect, and where.

They can be assembled with minimal wiring, and with that, avoid possible damages on the board that can happen when having to wire too many different parts. You will avoid compromising the noise interference, as well as the signal integrity.

2. More durable

Now let’s talk about something that is extremely important for all of us – the lifespan of the items we use and purchase. We all know that PCBs are usually really durable, and they can withstand almost everything we put them through. They don’t usually get damaged by moderate force, and they are relatively difficult to break. However, this all depends on the board itself, and some of them can be really delicate and easy to break.

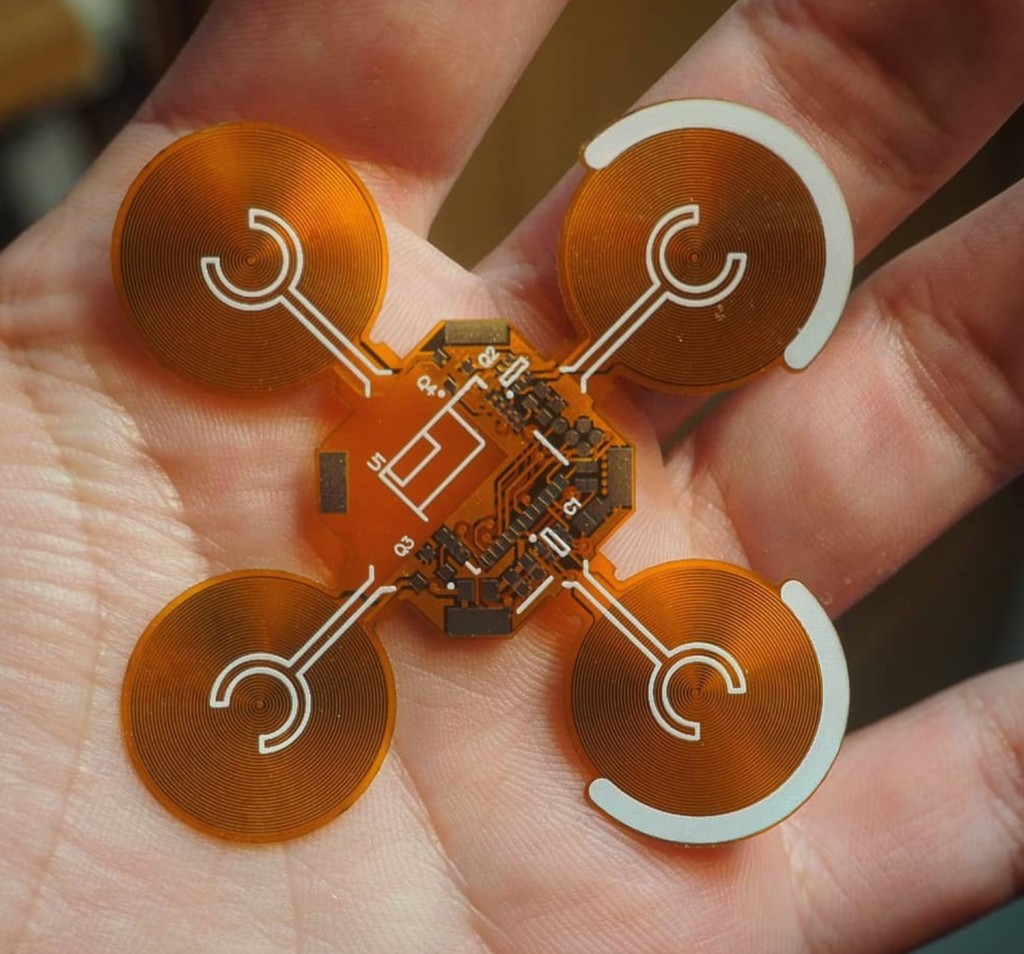

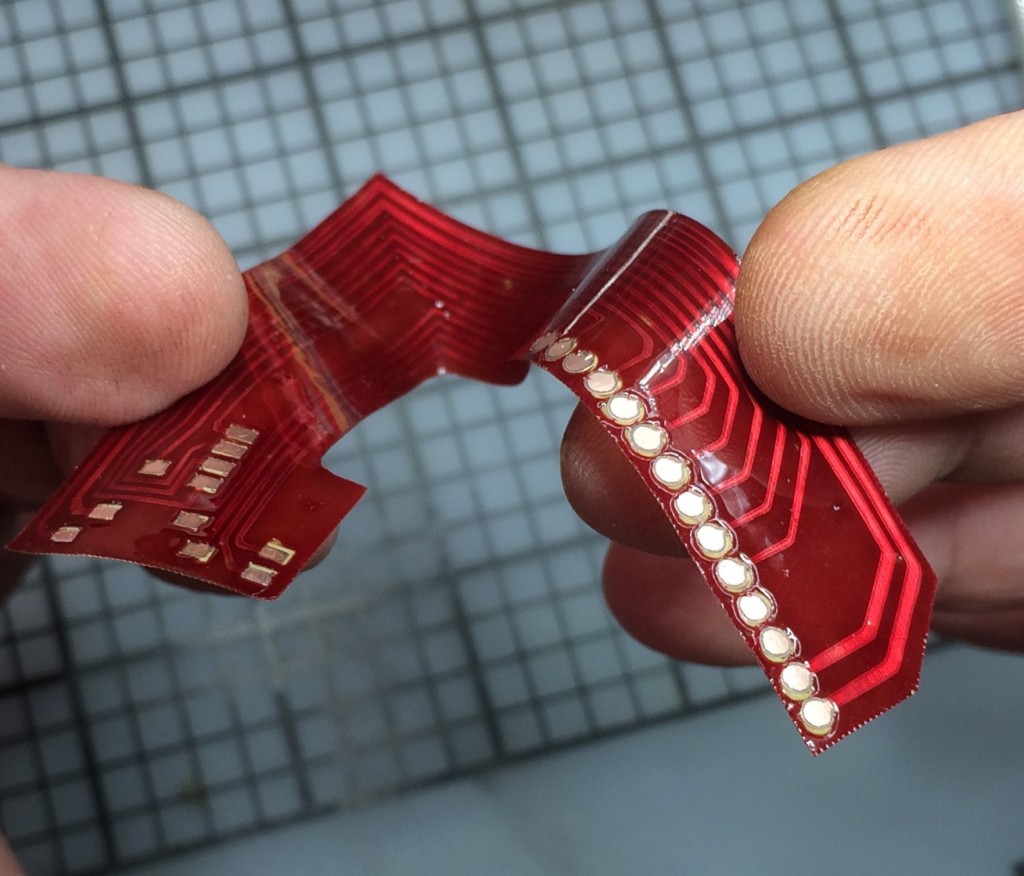

An elastic board is far better than a rigid one because it won’t get damaged if it bends, and the chances of it snipping in half are way smaller when compared to the traditional units. The materials used to create these items are more durable, and their compounds prolong the life of the board. They can withstand a harsher environment, temperature changes, and much more pressure and force than the traditional units. Because of this, they are perfect for the medical and automotive industry, as well as the military and even aerospace.

3. Small and lightweight

The last positive thing we are going to talk about when it comes to the elastic boards is that they are smaller than the traditional units, as well as lighter. Even though this may not seem like a huge improvement because most of the commonly used PCBs are already small and don’t weigh a lot, when we think about all the industries they are used in, space and weight do make a lot of difference.

Note that when it comes to direct comparison, they are 75 percent smaller than the traditional units, and with that, there can be more boards installed in one unit, when there is the need for that. This allows for better heat dispassion, as well as improved stability. They are less likely to break with usage, and they won’t damage any other parts of the devices, or cause overheating.

Note that these are some of the many pros that come with the elastic PCBs, and these are the biggest advantages and the main reasons why manufacturers choose them. According to pcbonline.com, various flexible materials are used in the manufacturing process of these boards, and you can choose the right one to fully benefit from the final type.

4. Production challenges

Now that we’ve seen the advantages of these boards, let’s talk about the disadvantages, and why they may not be used in every industry on the market.

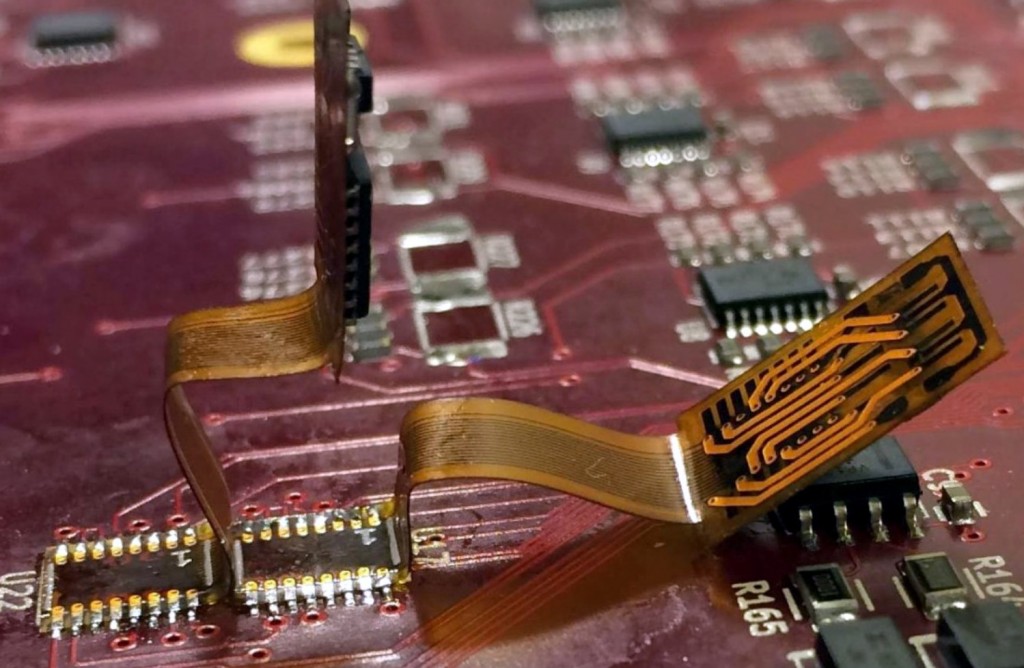

First of all, there can be a lot of production challenges, because the elastic materials are not as available as the traditional, rigid components are. This is still an extremely new process, and we haven’t figured out all the challenges that come with it.

These units do not follow the same blueprint as the traditional boards, so this has been noted as another difficulty that manufacturers can come across. Note that the complexity of the boards makes them more challenging to create, and there is more room for mistakes during the production process.

5. Higher cost

As we mentioned several times before, this type of PCBs is a new process, that uses different materials. They are made to be assembled and connected with ease, but the units themselves are more complex. This means that the production costs are going to be increased, and the manufacturers will need to adapt and purchase new equipment.

In certain applications, the cost will be even higher, and this is said to be mainly because of the poor utilization of the panels. However, it is expected that in time, these costs are going to decrease and that there won’t be a huge difference between production traditional, rigid boards, and the new and improved elastic PCBs.

6. Difficult to repair

The final item that is seen as a negative side is that the printed circuit boards are much more difficult to repair. We are used that the traditional units are relatively easy to fix in case there is an issue with them, and most of us have fixed a board on our own. Note that they are used pretty much everywhere, and you can find one even in your remote.

However, when it comes to the flexible units, they are more complex, and they are not going to be as easy to repair as the rigid ones. So, in case something happens to the board, if it gets damaged, broken, or even disconnected, most users will not be able to fix the issue on their own. The fact that everything will need to go through an official service makes the reparation process much more difficult, time-consuming, and ultimately, more expensive.

It is said that in at least half of the cases, the units will not be fixable and that it is going to be better to just replace them.

These are some of the advantages and disadvantages of elastic printed circuit boards. They are said to be the units of the future, and the pros definitely outweigh the cons. There is of course room for improvement, and it is expected for these boards to become more available and more commonly used in the next few years.